We repair balancing machines of any manufacturer

- In 95% of cases, it is an alternative to buying a new balancing machine.

- The work can be carried out within 2-3 days at the customer’s site.

- We repair native components or manufacture new ones, if appropriate.

- We repair old balancing machines of all types of any year of manufacture.

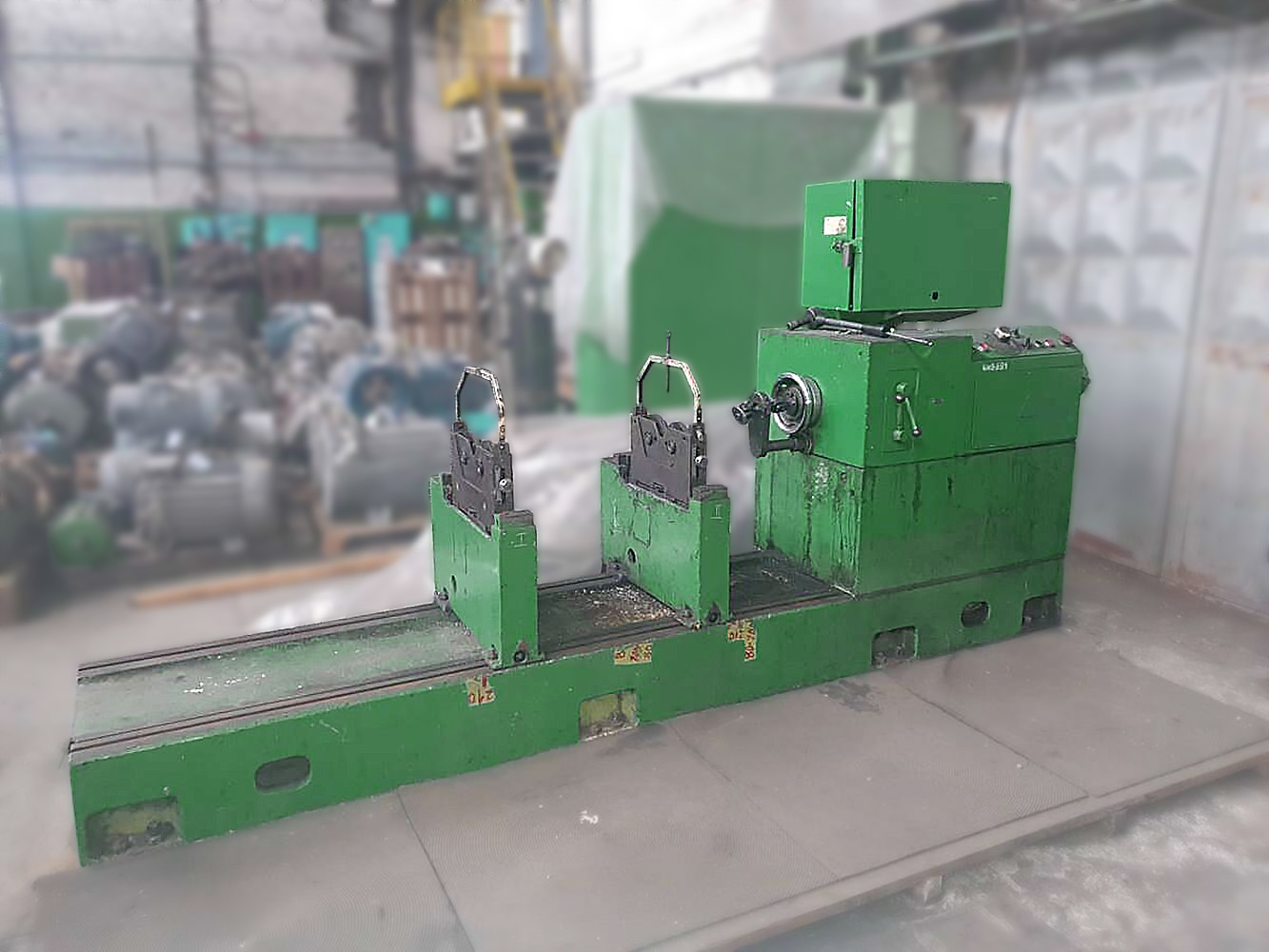

Before

After

UPGRADE YOUR BALANCING MACHINE

Every balancing machine includes mechanical, electrical and measuring parts. The mechanical part of most “old” machines is most often in good condition, since the support system and the drive unit are much more durable than the electrical and electronic parts. Repair of the electrical and electronic parts of balancing machines is in most cases impossible due to technically obsolete components.

Progress in measuring technique in recent years has resulted in a radical change in electronic measuring modules and balancing software. This has caused new functionality which has simplified and accelerated the balancing procedure, avoiding many errors in the balancing process.

Upgrading the electronic measuring unit, modernizing the electrical equipment and repair the mechanical components will result in a machine that is as accurate, productive and easy to use as a new one!

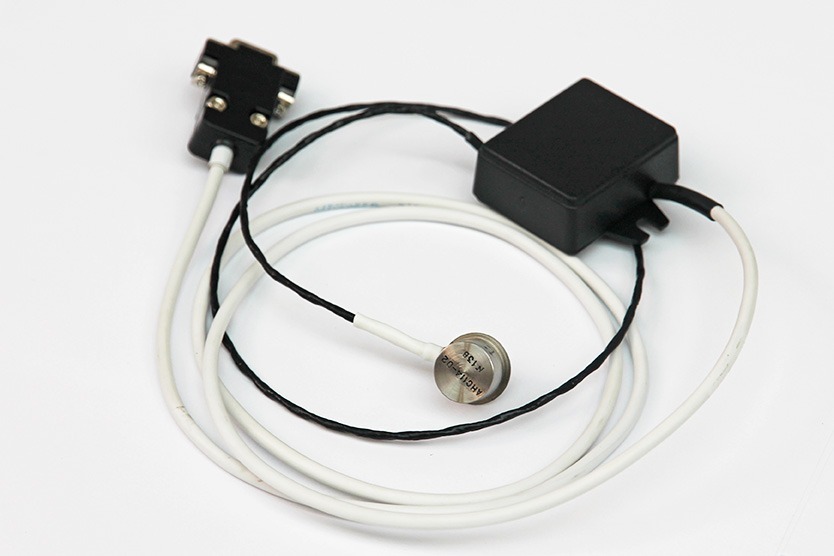

- New measuring system PAK-1 and vibration and speed sensors

- Frequency inverter electric drive

- New rollers, or adjustable roller units

- Manufacture of rotor belt drive for axial drive machine

- Installation a cardan rotor drive with a movable spindle

SELECT YOUR UPGRADE METHOD

On the customer’s site in one day

The measuring system, sensors, and electrical cabinet can be replaced on site. After delivery of all components, we will come and install and connect them at your workshop.

At our service center in Bratislava

If mechanical repairs are required, we can take the machine to our service center in Bratislava for a complete overhaul. We are ready to manufacture any damaged or worn parts for your balancing machine (rollers, spindles, supports).

NEW COMPONENTS FOR MODERNIZATION OF YOUR MACHINE

1. Replacement of the balancing system

2. Installation of new electrical equipment

3. New rollers or assembled roller units

4. Installation of belt drive part for axial drive machine tools

5. Installation of axial drive part for belt-driven machine tools

WE RESOLVE ANY ISSUE WITH YOUR BALANCING MACHINE

MODERNIZATION OPTION FOR YOUR BALANCING MACHINE

Basic

5-10% of the cost of a new machine

Replacement of the existing measuring unit with PAK-1 unbalance measuring unit, including:

- Installation PAK-1 unbalance measuring unit

- Installation of new vibration sensors and rotor speed sensor

- Replacement of all connecting cables

- Training of personnel in work skills

Main

20-30% of the cost of a new machine

Manufacturing and installation of electrical equipment and measuring and control unit, including:

- Installation PAK-1 unbalance measuring unit, new sensors

- Electrical cabinet with frequency inverter drive and control panel

- Asynchronous electric motor

- Replacement of all connecting cables

Advanced

40-60% of the cost of a new machine

Manufacture and installation of the following units:

- PAK-1 unbalance measuring unit and new sensors

- Electrical cabinet with frequency inverter drive and control panel

- New roller units or rollers only

- New belt drive or cardan drive

- Other modules can be modified